To maintain the tolerances and initial precision unchanged, all cast parts are normalised to prevent otherwise inevitable deformation over time.

(MEEHANITE GD250, BS1452 GRADE 17, DIN 1691 GG25 ASTM-A48 GRADE 35, ISO-R185 GRADE 25)

(MEEHANITE SFP 600, BS2789 37/3, DIN 1693 GGG60, ASTM-A536 80-55-06, ISO-R1083 600/3)

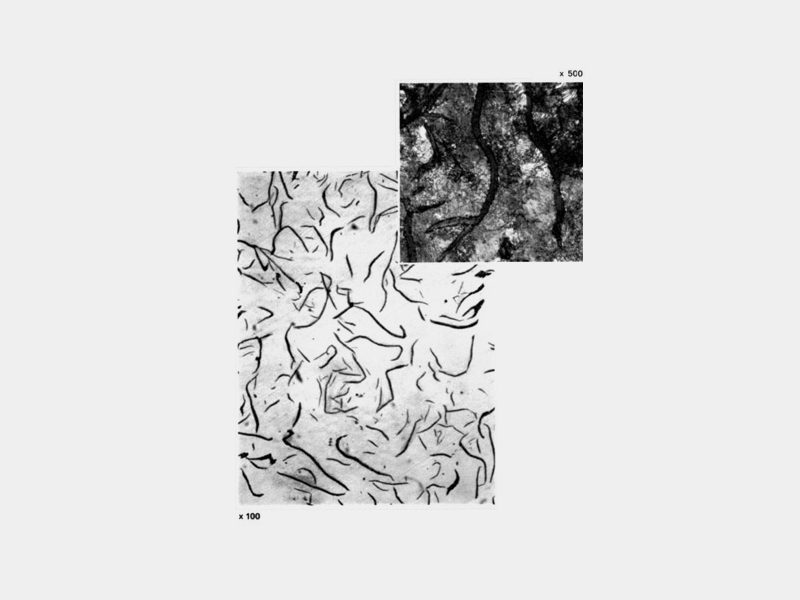

Nodular cast iron is a particular type of cast iron (an iron-carbon alloy with carbon content from 3.4% to 3.7%) where the carbon (or rather, the graphite) is in the form of spherical nodules. They are immersed in a metal matrix whose structure depends on chemical composition, cooling speed in the solidification phase and any thermal treatments that may be carried out.

The formation of nodules is achieved by addition of “nodulizing” elements such as magnesium, cerium or yttrium into the melt.

The particular spheroid structure offers a number of advantages in terms of mechanical properties of the material. The spherical form in fact, reduces the concentration of tension inside the material and, as it has a shape which has the smallest surface area at a given volume, this is the material which causes less damage to the metal matrix, making it possible to obtain superior properties compared to those of grey cast iron. Lastly, nodular cast iron is the only ductile cast iron, i.e. it can withstand plastic deformation.

The main mechanical properties of nodular cast iron include mechanical resistance similar to steel, hardness, elongation and toughness and a high resistance to wear and fatigue. Oxidation resistance is significantly higher than that of grey cast iron.

It also has good vibration damping and absorption properties and low friction coefficient.

"*" indicates required fields